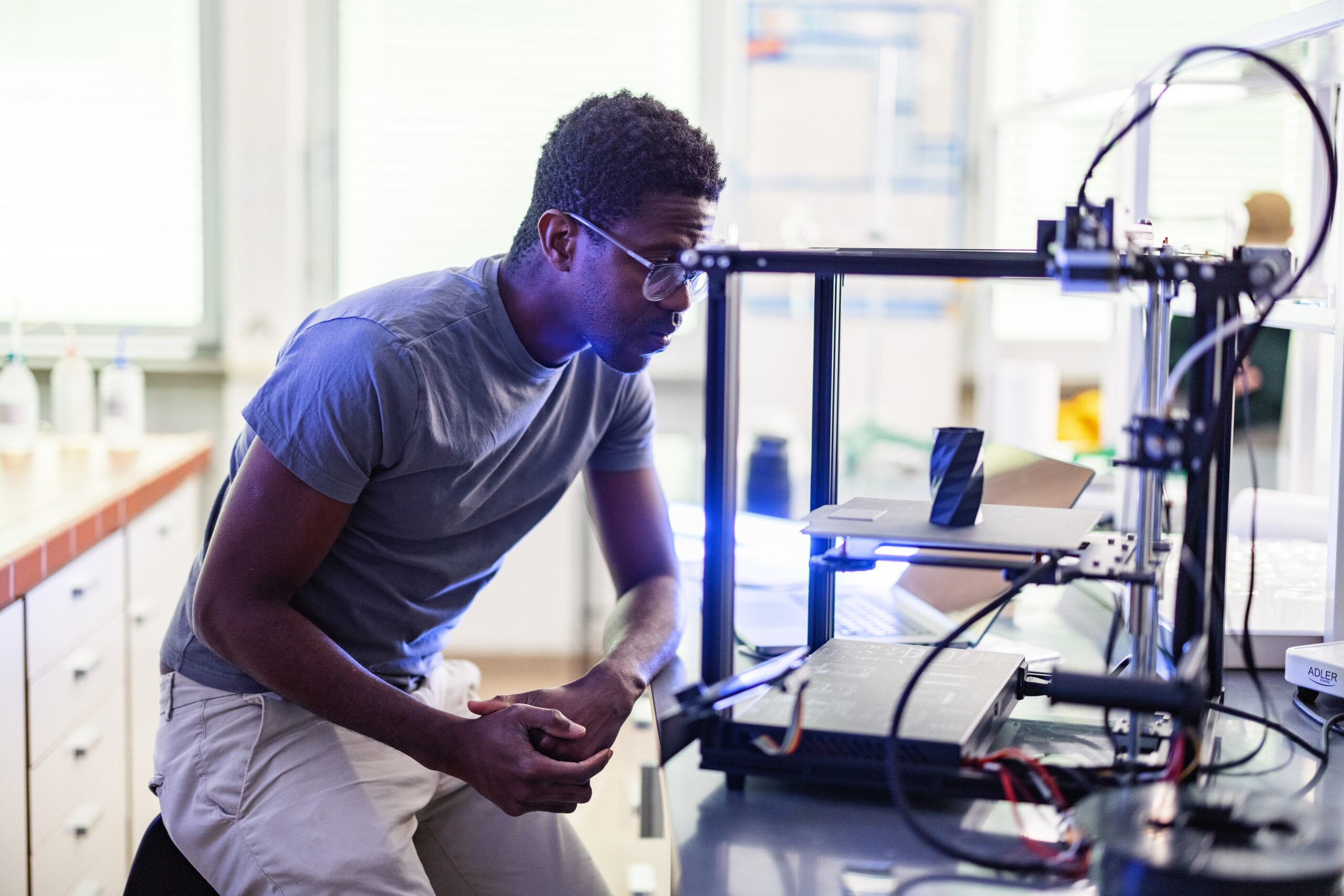

Volatile organic compounds (VOCs)

During operation, 3D printers release a complex mixture of volatile organic compounds that often exceeds 200 distinct species. VOCs easily evaporate into the air and can be inhaled.

Health impact

Many detected VOCs are known irritants, odorants, and carcinogens. Short-term exposure can cause eye, nose, and throat irritation in addition to headaches and nausea. Long-term exposure is associated with damage to the liver and central nervous system, cardiovascular disease, cancer, and asthma.

Resin hazard

In the vat polymerization of 3D printing technique, a vat filled with a resin is cured — or hardened — into a solid by exposure to UV light. The uncured resin itself is a source of VOCs that can be emitted even when the printer is simply loaded and turned off.

Fine and ultrafine particles (UFPs)

UFPs are generally smaller than 100 nanometers. Due to their minuscule size, they can be inhaled deep into the lungs, absorbed into the bloodstream, and potentially even reach the brain. Research found that particle emissions could reach up to one trillion particles per hour. In poorly ventilated spaces, particle mass concentrations (PM2.5) near an operating printer can exceed outdoor levels found near a busy highway.

Other hazards

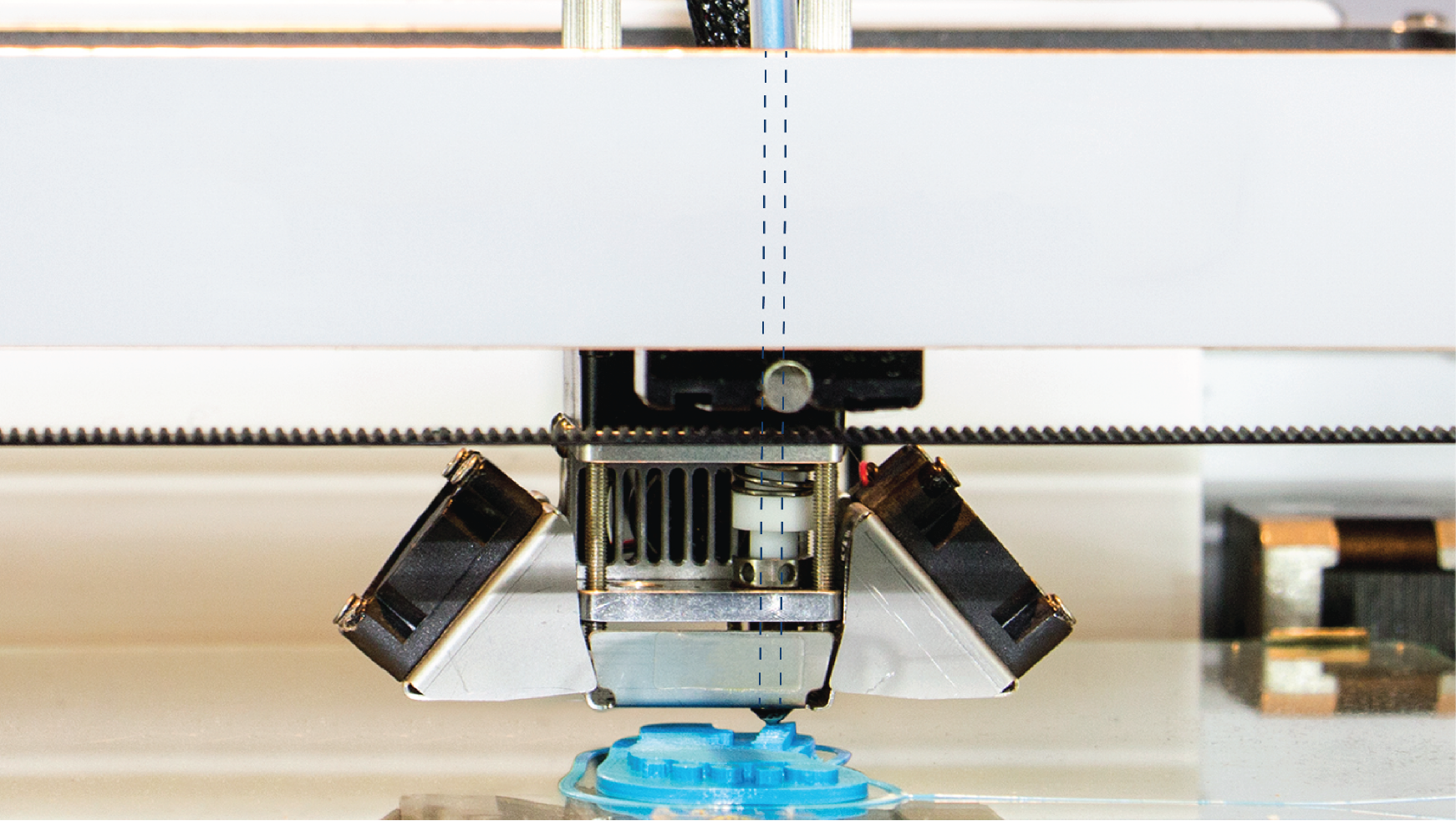

In addition to airborne emissions, the 3D printing process presents several physical safety risks:

- Dermal Exposure: Resins and solvents contain sensitizers that can cause allergic reactions and skin irritation.

- Burns: Contact with hot surfaces, such as the heated nozzle and build plate, poses a risk of burns

- Mechanical and Electrical: Hazards exist from unguarded moving parts and internal electrical components.